Leading Zero Liquid Discharge Plant Manufacturers in India

Uttamenergy is a leading ZLD plant manufacturers in India, and provides ZLD solutions (Zero liquid discharge) for molasses-based distilleries or ethanol facilities that preserve resources and safeguard the environment by accumulating water and renewable energy.

Zero liquid discharge (ZLD) is an innovative and sustainable approach to industrial wastewater treatment that aims to eliminate the discharge of liquid effluent from a facility.

This process involves the treatment and recovery of wastewater, resulting in a complete utilization of resources and minimal environmental impact. ZLD is particularly important in industries such as distilleries and ethanol plants, where wastewater discharge can have significant negative effects on the environment.

Our expertise in this area has allowed us to develop efficient and cost-effective ZLD solutions that not only preserve resources but also safeguard the environment.

Our ZLD solutions can be generated by either bio methanation or incineration, depending on the specific requirements of the facility.

Uttamenergy: The Leading ZLD Plant Manufacturers in India

What is Zero Liquid Discharge?

Zero Liquid Discharge (ZLD) is a wastewater treatment process that aims to eliminate the discharge of liquid waste from an industrial plant into the environment.

In this process, all the effluent generated by an industrial facility is treated and purified through a combination of various technologies, such as reverse osmosis, evaporation, and crystallization, until it becomes free of any liquid waste.

ZLD is an environmentally friendly and economically sustainable solution for industries that produce large volumes of liquid waste, such as distilleries, textile mills, power plants, and pharmaceutical manufacturers.

The benefits of ZLD include the conservation of water resources, the reduction of environmental pollution, and the recovery of valuable by-products, such as salts and minerals.

Our solutions help industries to preserve resources and safeguard the environment by accumulating water and renewable energy, thereby reducing their carbon footprint.

Zero Liquid Discharge Plant Solution in India

Uttamenergy Limited offers several types of zero liquid discharge plants, each with unique features and benefits, catering to diverse requirements.

The first type of plant is the Bio-methanation based ZLD plant:

In this process, the effluent from the distillery is treated in a bio-digester, which significantly decreases the BOD/COD content by creating biogas.

This biogas can be used as an auxiliary fuel in the boiler, generate electricity using gas engines or can be purified for use as CNG.

The digestate from the bio-methanation process is concentrated in a multiple-effect evaporator to recover water, which can be used for various purposes.

The concentrated digestate can be further transferred to either bio-composting or a dryer, yielding manure.

The second type of plant is the Incineration based ZLD plant:

In this process, the effluent from the distillery is concentrated in a multiple-effect evaporator before being directly incinerated in the combustion chamber above the grate in the incineration boiler. The combustor with travelling grate stokers is preferable for fuel flexibility.

Supplementary fuel such as bagasse, wood chips, rice husk, or coal is always necessary for optimal and sustainable combustion. This process is suitable for distilleries with high TDS (Total Dissolved Solids) content in their effluent.

Both types of plants have unique features and benefits. The Bio-methanation based plant is eco-friendly and economical, as it produces biogas, which can be used as an auxiliary fuel, generate electricity, or purified for use as CNG.

It also produces manure as a by-product, which can be used as a fertilizer. The Incineration based plant is highly effective in treating high TDS effluent and yields ash as a by-product, which can be used as a raw material in cement production.

Both types of plants help to conserve water resources and protect the environment by reducing pollution and waste.

In conclusion, Uttamenergy provides innovative and sustainable zero liquid discharge plant solutions and stands as a leading zld plant manufacturers to help the distillery industry achieve zero liquid discharge and contribute to a greener future.

Why Choose Uttamenergy as your ZLD plant Manufacturers?

Uttamenergy is a leading zero liquid discharge plant manufacturers in India with extensive experience and expertise in designing and manufacturing ZLD solutions for various industries, including molasses-based distilleries or ethanol facilities.

The company has a proven record of accomplishment of providing customized and innovative ZLD solutions that preserve resources and safeguard the environment.

Uttamenergy’s team of skilled engineers and technicians ensures that each ZLD plant is designed and manufactured to the highest standards. They use innovative technologies and advanced engineering practices to ensure that the ZLD solutions are efficient, reliable, and cost-effective.

The company has successfully executed various ZLD projects for clients across India, and the customers have been highly satisfied with the results.

For instance, one of our clients, a leading sugar and ethanol producer in Maharashtra, India, reported a significant reduction in water consumption and waste generation after implementing the ZLD solution provided by Uttamenergy.

The client also reported increased profitability due to the recovery of valuable by-products such as gypsum and sodium carbonate.

Another client, a leading chemical manufacturer in Gujarat, India, reported a reduction in operational costs and environmental impact after implementing Uttamenergy’s ZLD solution. The client recovered and reused valuable resources such as water and salt, leading to significant cost savings.

Overall, Uttamenergy’s expertise and experience in designing and manufacturing ZLD solutions make them an excellent choice for companies looking to implement environmentally sustainable and cost-effective solutions.

The positive customer feedback and case studies further demonstrate the effectiveness and reliability of our ZLD solutions.

ZLD Plant Installation and Maintenance:

Installing and maintaining a zero liquid discharge (ZLD) plant requires careful planning, engineering expertise, and regular maintenance.

The installation process begins with a thorough assessment of the customer’s requirements and site conditions, followed by the design and construction.

The plant must be built to meet local regulatory requirements and industry standards to ensure compliance and minimize environmental impacts.

Once the plant is operational, regular maintenance is crucial to ensure long-term success. Maintenance activities include monitoring the plant’s performance, conducting routine inspections, replacing worn-out parts, and cleaning the equipment.

In addition, periodic upgrades and modifications may be necessary to keep up with changing regulatory requirements and industry standards.

We offer a full range of services, including project planning, engineering, construction, and ongoing maintenance. We also provide training and support for plant operators and can assist with regulatory compliance and permit applications.

Our team of experts works closely with customers to ensure that ZLD plants are designed and installed to meet customer’s specific requirements and local regulatory requirements. We also provide ongoing maintenance services to help ensure the plant’s long-term success and optimal performance.

ZLD Plants in India:

India is facing severe water scarcity issues, with many regions experiencing water stress and depletion of groundwater reserves. As a result, the implementation of zero liquid discharge (ZLD) technology has become a crucial solution to mitigate water pollution and conserve water resources.

Uttamenergy has been at the forefront of providing effective ZLD solutions to various industries.

We have extensive experience in designing, building, and maintaining ZLD plants in India, which have helped businesses comply with regulatory requirements and reduce their environmental impact.

The company’s ZLD solutions have been successful in treating a wide range of wastewater streams, including industrial effluents, municipal sewage, and brine generated from desalination plants.

Our ZLD plants incorporate advanced technologies such as membrane filtration, evaporation, and crystallization, which can effectively treat wastewater and recover valuable resources such as salts and minerals.

Our ZLD solutions have been widely recognized for their effectiveness in preserving water resources, reducing environmental pollution, and lowering operating costs for businesses.

Our commitment to innovation, sustainability, and customer satisfaction has made them a top choice for companies looking to implement ZLD technology in India.

Conclusion:

Zero liquid discharge technology is an effective solution for businesses looking to reduce water consumption, comply with regulatory requirements, and minimize their environmental impact.

We offer innovative and cost-effective solutions for various industries.

Our extensive experience and expertise make them a top choice for businesses looking to implement this technology.

Contact Uttamenergy to learn more about our tailored solutions and commitment to sustainable practices.

Typically, distilleries’ effluent, such as wasted wash/slop/vinasse, is proportional to 9 to 12 times daily ethanol output, with a solid percentage of 11 to 14%. The following is an example of an effluent analysis:

● Colour as deep reddish brown

● Aromatic odour

● Specific gravity as 1.05

● pH as 4.5

● BOD as 50000-55000

● COD as 80000-85000

● Total nitrogen as 927 mg/l

● Total phosphate as 45.6 mg/l

● Total potassium as 61.0 mg/l

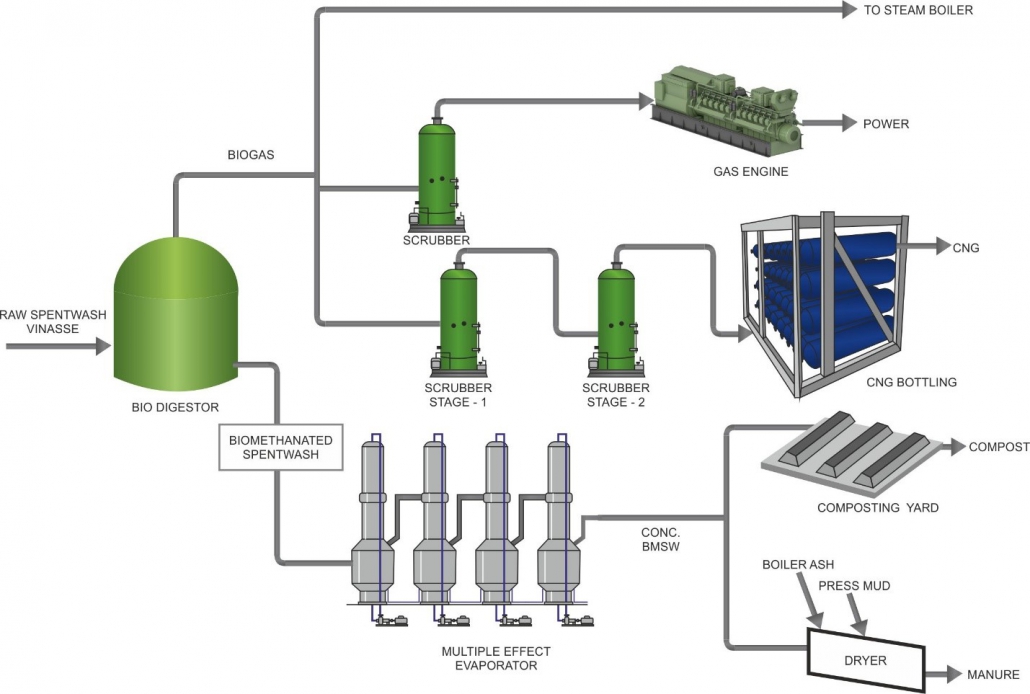

ZLD solutions can be generated by bio methanation or incineration. Please refer to the schemes demonstrated below.

Bio Methanation Route

Effluent vinasse/slop from the distillery is treated to bio methanation in a bio digestor, which significantly decreases the BOD/COD content by creating biogas with a concentration of 50-55% on a volume basis. This biogas can be used in one of three ways, all of which are completely reliant on market economics.

Option-1 : Use as an auxiliary fuel in the boiler.

Option-2 : Generate electricity using gas engines after purifying biogas to the necessary standard.

Option-3 : Refill CNG canisters by purifying biogas with a methane level of more than 95%.

To recover water, the digestate from the bio methanation process is concentrated in a multiple-effect evaporator. To yield manure, the concentrate will be further transferred to either bio-composting or a dryer.

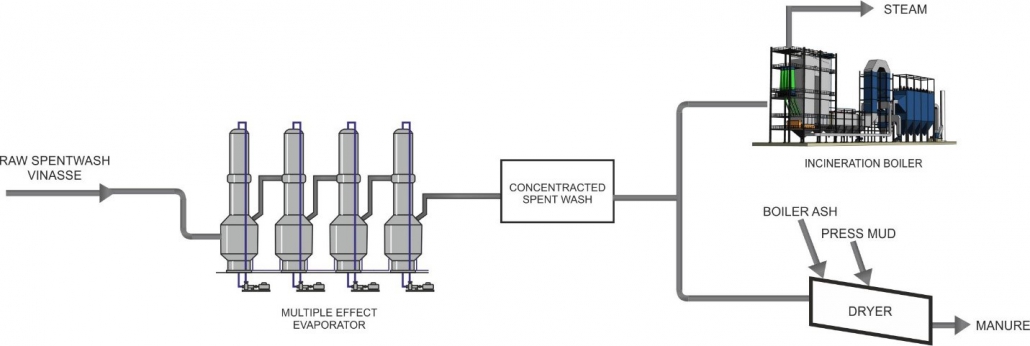

Incineration Route

The distillery’s vinasse/slop effluent is concentrated to 52-60% solids in a multiple-effect evaporator before being directly incinerated in the combustion chamber above the grate in the incineration boiler.

Supplementary fuel, such as bagasse, wood chips, rice husk, or coal, is always necessary for optimal and sustainable combustion. For fuel flexibility, combustors with travelling grate stokers are preferable.