Top Manufacturer of Cost-Effective Bagasse Dryers in India

Welcome to Uttamenergy, the leading manufacturer of cost-effective sugarcane bagasse dryers in India. We understand the significance of having a reliable and efficient bagasse dryer in the sugar industry. Our expertise lies in providing state-of-the-art bagasse drying solutions that optimize the utilization of bagasse, a byproduct of sugarcane processing.

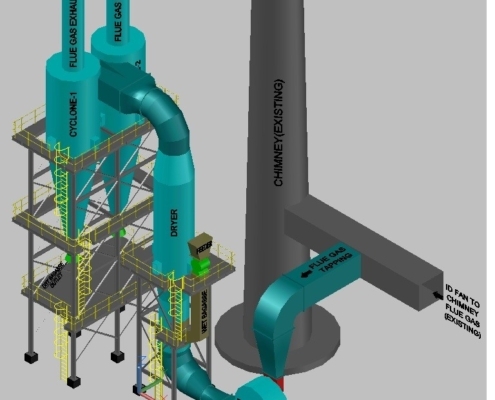

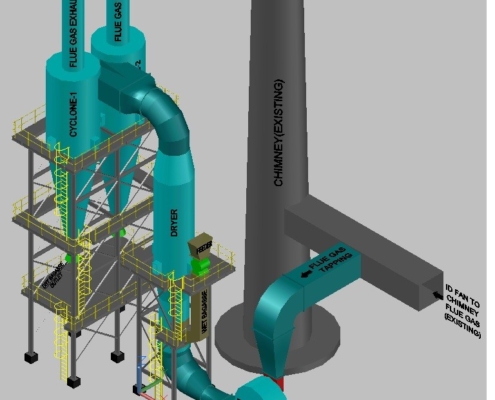

Bagasse dryers are our in-house developed innovative product through R&D efforts to dry wet bagasse by utilizing the waste flue gas energy dumped through chimney.

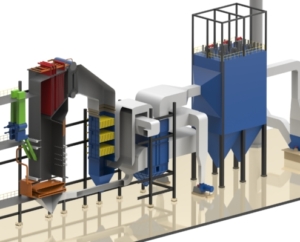

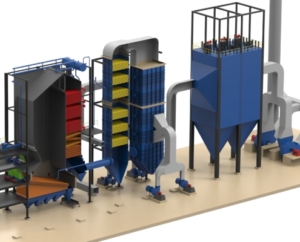

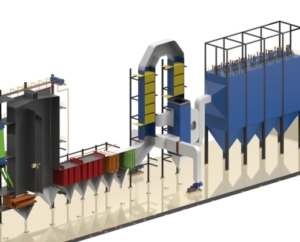

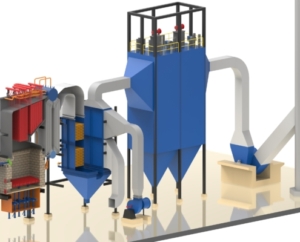

Flue gases from the boiler are made to pass through dryer under forced draft and with wet mill bagasse being fed at the bottom of the dryer through a rotary air lock feeder.

Due to concurrent flow wet bagasse gets carried upward along with hot flue gas at a calculated velocity based on Average Particle Retention Time (APRT). During this process, bagasse moisture evaporates and dried bagasse is subsequently separated through high efficiency cyclone separators.

As prominent bagasse dryer manufacturers, we recognize the critical role bagasse dryers play in sugar mills. These dryers efficiently remove moisture from bagasse, enhancing its calorific value and making it an excellent renewable energy source. By investing in a high-quality bagasse dryer, sugar mills can reduce dependency on fossil fuels and contribute to a greener and more sustainable future.

At Uttamenergy, we cater to the specific needs of sugar mills, offering advanced and customized bagasse dryers that maximize performance and energy efficiency. Our dryers are designed to handle large quantities of bagasse while ensuring optimal drying conditions. We collaborate closely with bagasse suppliers and sugar mills to deliver reliable drying solutions that meet their operational requirements.

With our bagasse dryers in India, sugar mills can enhance their productivity, reduce operational costs, and minimize environmental impact. We take pride in being a trusted partner to the sugar industry, providing cutting-edge technology and exceptional customer support.

Stay tuned to learn more about our range of bagasse dryers and the benefits they offer to sugar mills. Uttamenergy is committed to revolutionizing the bagasse drying process and supporting the sugar industry’s growth and sustainability.

Top Manufacturer of Cost-Effective Bagasse Dryers in India:

Benefits of Uttamenergy’s Sugarcane Bagasse Dryers:

When it comes to bagasse drying, Uttamenergy stands out as a trusted manufacturer, offering a range of innovative solutions for the sugar industry. Our bagasse dryers deliver numerous benefits that help sugar mills enhance their operations and achieve sustainability goals.

1. Increased Productivity:

Uttamenergy’s bagasse dryers are designed to handle large volumes of bagasse efficiently. By reducing the moisture content of bagasse, our dryers increase its calorific value, resulting in higher energy production. This enhanced productivity allows sugar mills to optimize their processes and maximize revenue generation.

2. Reduced Energy Consumption:

Our bagasse dryers are equipped with advanced technology that ensures optimal energy utilization. By efficiently drying bagasse, they minimize the need for additional energy sources, such as fossil fuels. This reduction in energy consumption not only lowers operational costs but also reduces the carbon footprint of sugar mills.

3. Improved Quality of Dried Bagasse:

Uttamenergy’s bagasse dryers employ precise temperature and airflow control systems, ensuring uniform drying and maintaining the quality of the dried bagasse. This high-quality bagasse can be utilized for various applications, including power generation, production of biofuels, and animal feed, enhancing the value and versatility of bagasse as a byproduct.

4. Successful Installations and Satisfied Customers:

We have a proven track record of successful installations in sugar mills across India. Our bagasse dryers have consistently delivered exceptional performance and customer satisfaction. By partnering with leading bagasse suppliers and sugar mills, we have established ourselves as a reliable and preferred choice for bagasse drying solutions.

At Uttamenergy, we prioritize customer needs and provide comprehensive support throughout the installation and operation of our bagasse dryers. Our experienced team ensures seamless integration and assists with maintenance and troubleshooting, ensuring uninterrupted performance and long-term reliability.

By choosing Uttamenergy’s bagasse dryers, sugar mills in India can experience increased productivity, reduce energy consumption, improved bagasse quality, and ultimately, contribute to a sustainable and profitable future.

Why Choose Uttamenergy for bagasse dryers in India:

When it comes to bagasse dryer manufacturers, Uttamenergy stands out for several compelling reasons. We go above and beyond to provide our customers with the best solutions tailored to their needs.

Here’s why you should choose us:

1. Innovation:

At Uttamenergy, innovation is at the core of our operations. We continuously invest in research and development to bring cutting-edge technology and advancements to our bagasse dryers. Our team of experts works tirelessly to improve efficiency, productivity, and sustainability, ensuring that our customers benefit from the latest innovations in bagasse drying.

2. Customer Service:

We take pleasure in providing excellent customer care. Our devoted team is committed to providing individualized solutions and comprehending the particular needs of each customer. Customer satisfaction is our top priority, and we work hard to go above and beyond at every turn, from the initial consultation to the after-sales assistance. We are here to support you every step of the way because your success is also our success.

3. Sustainable Solutions:

Sustainability is a crucial aspect of our approach. Our bagasse dryers are designed to optimize energy consumption, reduce emissions, and minimize waste. By utilizing state-of-the-art technology and sustainable practices, we help sugar mills achieve their environmental goals while maximizing their operational efficiency. Choosing Uttamenergy means embracing a sustainable future for your bagasse drying needs.

4. Extensive Industry Experience:

With years of experience in the industry, we have developed a deep understanding of the challenges faced by sugar mills and bagasse suppliers. Our expertise enables us to provide comprehensive solutions that address specific requirements and deliver tangible results. We have successfully installed bagasse dryers in numerous sugar mills across India, earning the trust and satisfaction of our valued customers.

5. Reliable Partner:

When you choose Uttamenergy, you choose a reliable partner for your bagasse drying needs. We adhere to the highest standards of quality, ensuring that our equipment is robust, durable, and built to last. Our commitment to excellence and our strong reputation in the industry make us a trusted choice for bagasse dryer solutions.

By choosing Uttamenergy as your bagasse dryer manufacturer, you gain access to innovative technology, exceptional customer service, sustainable solutions, industry experience, and a reliable partnership. Contact us today to discover how we can meet your bagasse drying requirements and help you achieve optimal results.

Uttamenergy’s Customizable Solutions of Bagasse dryers:

At Uttamenergy, we take pride in offering bagasse dryers that can be customized to meet the specific needs of each sugar mill. We understand that every mill has unique requirements, and our goal is to provide tailored solutions that optimize performance and efficiency.

Here’s how our customizable solutions can benefit your sugar mill:

1. Tailored Design:

Our bagasse dryers can be designed to accommodate the size and capacity of your sugar mill. Whether you have a small-scale mill or a large-scale operation, we can customize the dryer’s dimensions to fit your available space. Additionally, we consider the specific bagasse characteristics of your mill to ensure optimal drying performance.

2. Energy Optimization:

We recognize the importance of energy efficiency in the sugar industry. Our team works closely with you to understand your energy requirements and develop a bagasse drying system that minimizes energy consumption. By utilizing advanced technologies and incorporating energy-saving features, we help you reduce operational costs while maintaining high drying efficiency.

3. Process Customization:

Each sugar mill has its unique process requirements, and our bagasse dryers can be customized to align with your specific needs. We collaborate with you to analyze your drying process and tailor the system accordingly. From moisture reduction levels to drying time, we optimize the drying parameters to achieve the desired bagasse quality and moisture content.

4. Successful Customization Projects:

Over the years, we have successfully executed numerous customization projects for sugar mills. These projects have involved adapting our bagasse dryers to match different mill layouts, integrating specific automation and control features, and meeting specific capacity requirements. Our expertise in customization has resulted in improved drying efficiency, enhanced productivity, and customer satisfaction.

Conclusion:

Uttamenergy is a top bagasse dryer manufacturer in India that provides cost-effective and sustainable solutions to meet the specific needs of sugar mills. Their bagasse dryers offer numerous benefits, including increased productivity, reduce energy consumption, and improved quality of dried bagasse. With a focus on innovation, customer service, and customization, Uttamenergy is a trusted partner for sugar mills looking to improve their bagasse drying process.

If you’re interested in learning more about Uttamenergy’s bagasse dryers or want to request a quote, don’t hesitate to contact them today. Their experienced team is ready to provide you with the information and support you need to make an informed decision.

Additional Information

This dried bagasse is continuously evacuated from the bottom of the cyclone(s) through air-lock valves for onward feeding to the boiler. Adequate automation including differential pressure monitoring are provided.