Building your future with innovation and engineering

The multidisciplinary engineering team at Uttamenergy has extensive knowledge of the equipment, processes, and controls affiliated with power plants and biomass-based steam boilers.

Power Plants

Revolutionizing Power & Energy

- Preliminary feasibility and project report

- Comprehensive power plant design

- Collaborating in project management

- Design and analysis of power plant piping

- Energy assessments and efficiency enhancements

- Conversion of water-cooled condensers to air-cooled condensers

Steam Boilers

Top-of-the-class technology for steam generation

- Optimization of capacity and efficiency

- Conversion of coal-fired boilers to biomass-fired boilers

- Retrofitting a boiler for a fuel transition

- Technology for remote performance monitoring

Our Quality is the reflection of perfection

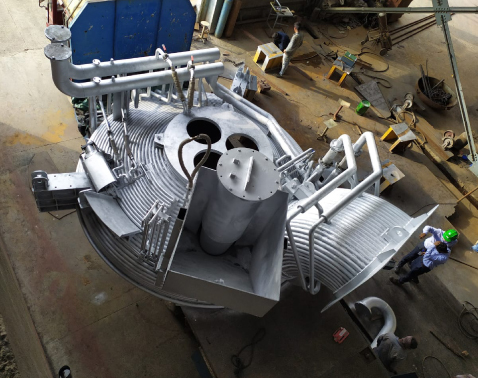

Uttamenergy, with its cutting-edge production facilities, adheres to quality standards in accordance with ISO 9001 certification and safety requirements in accordance with ISO 45001:2018 certification. It offers the ability to manufacture and supply pressure vessels such as steam boilers, steam drums, steam accumulators, decelerator tanks, storage tanks, steam piping, etc, as well as non-pressure part products such as chimneys, tankages, and structural components based on the client’s manufacturing drawing. Furthermore, we provide engineering services for developing production drawings from process drawings.

Name that promises success & assures a better future

Uttamenergy now offers O&M solutions for comprehensive power plants, sugar plants, and ethanol plants. Our experience and skills come from decades of managing and operating sugar plants, co-generation plants, and distillery plants on Uttam Group assets.

We offer more than just traditional retrofitting

We provide retrofitting and revamping solutions for existing sugar plants, co-generation plants, and distillery facilities in order to enhance capacity and improve performance, resulting in operational excellence and a faster payback of the investment. Uttamenergy has successfully retrofitted and recommissioned any such units, which now run within the criteria we have established.

Leveraging tech to drive a better experience

RPMS allows any user from anywhere in the globe to monitor the state of the boiler or power plant (using valid credentials). It provides data and trends and sends alerts in the event of a parameter change, a breakdown, or an emergency shutdown. It also creates trends and reports in the formats specified by the user.